Theory of Constraints in Healthcare

Have you ever heard of The Goal? Alex Rojo? These ideas had so much impact on things in my career that they are ingrained into my neurons.

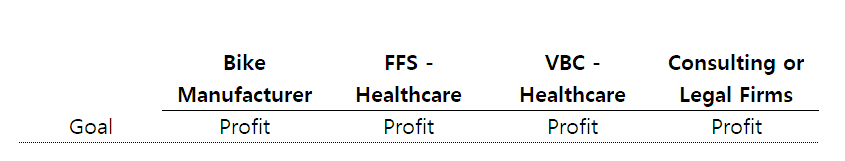

All businesses, from a bike manufacturer to a hospital have one simple goal: to make a profit. That doesn't mean they don't also try to make life good for those employed by them. Or that they can't have other side objectives like providing meaningful community investments. But a business is born to make a profit, that is "the Goal".

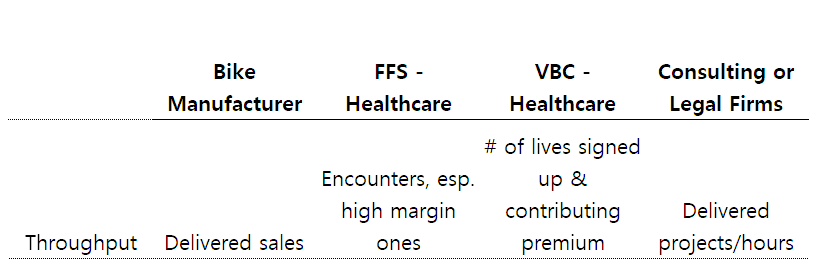

The goal is reached by (among other things) delivering the product that your customers purchase, or "Throughput". Building a bike(s) & delivering to a customer is throughput.

The stuff that goes into what you deliver is inventory. Bike frames, bike tires, chains, etc.

Anything else you pay for is operational expense. The expert laborers that you hire and pay to assemble the bikes, the marketing required to get your name in the market - all operational expense.

Throughput, inventory, operational expense, got it?

To reach the goal and make a profit you need to increase your throughput. It turns out there is a clever insight that the capacity of your business is driven by the bottlenecks or constraints. Therefore, the theory of constraints says to increase the capacity of your system, increase the capacity of your bottlenecks. If Jim puts the wheels on the bike and is the slowest person on the production line, Jim's speed determines the speed of your production.

You need to identify where the "Jim's" are in your production line. Get them moving faster. Make sure everyone knows that & helps him get faster. Invest in training Jim. Once he is no longer the bottleneck, keep him successful & find the next constraint, repeat forever.

In specific terms manage your constraints: Identify, Exploit, Subordinate, Elevate, Repeat.

"But, we're not a bike shop, we're healthcare...I'm not sure it'd work here." It has. It does. It will. But it is different.

It feels impolite to mention that the goal of healthcare is the same as other businesses, but it is the best way to understand what's going on with it as a system.

Something simple like a bike maker is an easy foundation to understand. FFS (Fee For Service) reaches profit differently than VBC (Value Based Care) and Consulting/Legal firms offer an interesting parallel to both.

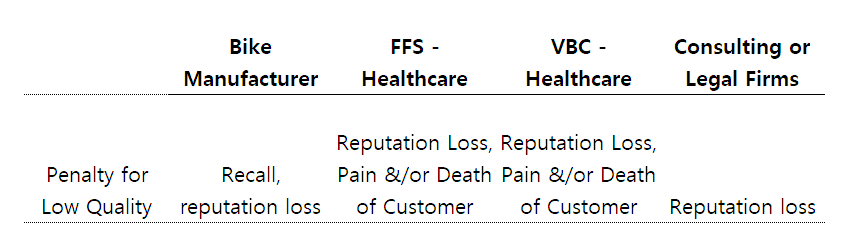

Where things really start to take a turn is in the impact your business has. While you lose business as a manufacturer or consulting shop, you don't often lose the lives of your customer.

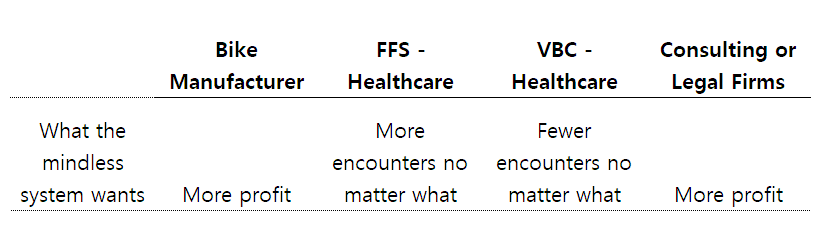

In all of this, it is a good reminder that a system like a business is a very simple creature, it is simply pursuing the goal that was laid out for it. As such, FFS healthcare just wants more and more encounters. It will do anything (sans the humans that control it changing things) to get more. Think of it like gravity, it is a constant force and without resistance will just pull everything toward it. In VBC, the gravity goes the opposite direction, it wants fewer encounters no matter what. Of course, there are counter forces that are built into the system like quality metrics & customer feedback that prevent those forces from dominating, but it is important to understand the direction the "gravity" pulls.

FFS throughput is encounters, some higher margin than others. When you provide more care than is needed that is also throughput. Variation & lack of process is ultimately rewarded as throughput because you are largely paid for each element of service that you give. Some billing mechanisms limit this importantly, e.g. DRG's that limit a payment for a particular episode of care, but largely the incentives go this way.

VBC throughput will go through a Rube Goldberg machine as most systems are not pure VBC, but from a theoretical standpoint the primary mechanism for VBC is the number of lives signed up and contributing premium.

So what?

Understanding the mechanics of throughput and constraints allows healthcare systems to optimize their operations similarly to a manufacturing line. The key is to pinpoint where the bottlenecks occur—be it in patient intake, diagnostics, treatment, or discharge processes—and then apply focused improvements. For example, if the diagnostic phase is slowing down patient flow, investing in faster, more efficient diagnostic tools and training can elevate this constraint, increasing overall throughput.

In healthcare, every step in patient care is like a stage in a production line, with each phase needing optimization to ensure the system runs smoothly. By adopting the theory of constraints, healthcare providers can enhance efficiency, improve patient outcomes, and ultimately increase profitability. This approach not only helps in managing operational expenses but also ensures that the delivery of care is consistent and effective. Just as in a bike shop, where improving the speed of the slowest worker accelerates the entire production, in healthcare, identifying and addressing the slowest points in patient care can significantly elevate the entire system's performance. Thus, embracing these principles can transform healthcare delivery, making it more efficient, patient-centered, and sustainable in the long run.